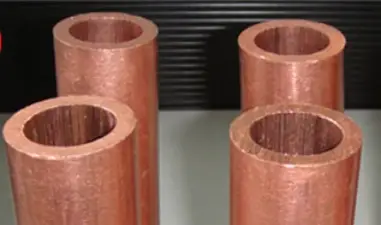

Copper Nickel 90/10 Pipes & Tubes are forged alloys of copper and nickel. Because it has 10–30% nickel, it is best for seawater environments. Also, iron and manganese are added in small amounts to make the metal stronger and more resistant to corrosion. It is a popular grade because it is easy to shape and tough. It is easy to cut and join. It is a natural defense against biofouling. It has some great qualities that make it perfect for use at cryogenic temperatures or very low temperatures. It kills bacteria and germs very well. In just two hours, it can kill 99 percent of germs.

Cuni 90/1010 Pipes & Tubes are used in many different fields, including offshore and marine, chemical processing, and a lot more. It is used to make saltwater pipes, fittings, valves, pump parts, and marine hardware in the marine and offshore industries. It is used to make heat exchangers, cooling plants, evaporator tubes, pumps, and water trim. It is also used in power steering tubes, brake lines, condenser plates, pressure vessels, and distiller tubes, among other things.

Because these alloys can be used for so many things, they have become very popular. It has a high antimicrobial property, and because it kills germs quickly, it is used a lot in places that need to be clean and sanitary, like kitchen appliances, hospitals, nursing homes, and other health care settings. It is used in marine water equipment because it doesn't rust very easily. It is used to make all kinds of fittings, including valves, pipes, and parts for pumps.

| Material Specification | ASTM B466/ ASME SB466 |

|---|---|

| WT | 0.1millimeter to 60 millimeter |

| Copper Nickel 90/10 Pipe Size standard | Schedule 40s, 10s, 160s, 80s, ½”- 6” Nominal Bore |

| Surface Finish | Bright, Cold Finish, Pickling, Annealing, Polished or as per need |

| Length Available |

10 to 12 meter Double Random Length 5 -7 meter Single Random Length |

| Technology to Manufacture | Cold Formed/ Hot |

| cupro nickel 90/10 Pipe various types | Welded, Seamless, EFW, ERW |

| Test Reports | PMI Test Reports, EN 10204 3.1, Mill Test Certificates, Mechanical Reports, Chemical Reports, Visual Inspection Reports, NABL Approved Lab Reports, Third Party Inspection, , Destructive and Non Destructive Test Reports |

| Cu-Ni 90/10 Pipe Standard ASTM | AMS, EN, AISI, JIS, GOST, GB, ASME, ASTM, DIN |

| Method | Hot Rolled/ Cold Rolled |

| UNS C70600 Pipe available Shapes | Square, Round, Box Section, Rectangle |

| STANDARD | UNS | WNR. |

|---|---|---|

| Copper Nickel 90/10 | C70600 | 2.0872 |

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Cu-Ni 90-10 | 88.6 min | 1.0 max | .05 max | 9-11 max | 1.8 max | 1 max |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 303-414 MPa | 43900-60000 psi |

| Tensile strength, yield (depending on temper) | 110-393 MPa | 16000-57000 psi |

| Elongation at break (in 254 mm) | 42.00% | 42.00% |

| Machinability (UNS C36000 (free-cutting brass) = 100%) | 20% | 20% |

| Shear modulus | 52.0 GPa | 7540 ksi |

| Poisson's ratio | 0.34 | 0.34 |

| Elastic modulus | 140 GPa | 20300 ksi |

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.94 g/cm3 | 0.323 lb/in3 |

| Nominal Copper Pipe Size | WT | Copper Nickel 90/10 Pipe OD | Weight | Copper Nickel 90/10 Pipe Weight | |||

|---|---|---|---|---|---|---|---|

| milimeter | inch | inch | milimeter | kilogram/Meter | Sched | Lb/ft | |

| 1/2″ | 2.769 | 0.0109 | 0.0840 | 21 | 1.268 | 40 STD | 0.0851 |

| 3.734 | 0.0147 | 1.621 | 80 STD | 1.088 | |||

| 3/4″ | 2.870 | 0.0113 | 1.050 | 27 | 1.684 | 40 STD | 1.131 |

| 3.912 | 0.0154 | 2.195 | 80 STD | 1.474 | |||

| 1″ | 3.378 | 0.0133 | 1.315 | 33 | 2.501 | 40 STD | 1.679 |

| 4.547 | 0.0179 | 3.325 | 80 STD | 2.172 | |||

| 1 1/4″ | 3.556 | 0.0140 | 1.660 | 42 | 3.385 | 40 STD | 2.273 |

| 4.851 | 0.0191 | 4.464 | 80 STD | 2.997 | |||

| 1 1/2″ | 3.683 | 0.0145 | 1.900 | 48 | 4.048 | 40 STD | 2.718 |

| 5.080 | 0.0200 | 5.409 | 80 STD | 3.361 | |||

| 2″ | 3.912 | 0.0154 | 2.375 | 60 | 5.441 | 40 STD | 3.653 |

| 5.537 | 0.0218 | 7.480 | 80 STD | 5.022 | |||

| 2 1/2″ | 5.516 | 0.0203 | 2.875 | 73 | 8.629 | 40 STD | 5.793 |

| 7.010 | 0.0276 | 11.411 | 80 STD | 7.661 | |||

| 3″ | 5.486 | 0.0216 | 3.500 | 89 | 11.284 | 40 STD | 7.576 |

| 7.620 | 0.0300 | 15.272 | 80 STD | 10.0253 | |||

| 4″ | 6.020 | 0.0237 | 4.500 | 114 | 16.073 | 10.0790 | |

| 8.560 | 0.0337 | 22.318 | 14.983 | ||||

| 6″ | 4.775 | 0.0188 | 6.625 | 168 | 19.252 | 12.924 | |

| 5.516 | 0.0203 | 20.0739 | 13.923 | ||||

| 5.563 | 0.0219 | 22.318 | 14.983 | ||||

| 6.350 | 0.0250 | 25.354 | 17.021 | ||||

| 7.112 | 0.0280 | 58.263 | 40 STD | 18.974 | |||

| 7.925 | 0.0312 | 31.334 | 21.036 | ||||

| 9.525 | 0.0375 | 37.285 | 25.031 | ||||

| 10.0973 | 0.0432 | 42.561 | 80 XHY | 28.573 | |||

| 12.700 | 0.0500 | 48.719 | 32.708 | ||||

| 8″ | 4.775 | 0.0188 | 8.625 | 219 | 25.233 | 16.940 | |

| 5.156 | 0.0203 | 27.198 | 18.259 | ||||

| 5.563 | 0.0219 | 29.286 | 19.661 | ||||

| 6.350 | 0.0250 | 33.308 | 20 | 22.361 | |||

| 7.036 | 0.0277 | 36.786 | 30 | 24.696 | |||

| 8.179 | 0.0322 | 42.352 | 40 | 28.554 | |||

| 9.525 | 0.0375 | 49.216 | 33.041 | ||||

| 10.0312 | 0.0406 | 53.085 | 60 | 35.638 | |||

| 12.700 | 0.0500 | 64.627 | 80 XHY | 43.388 | |||

| 10″ | 4.775 | 0.0188 | 10.0750 | 273 | 31.588 | 21.207 | |

| 5.563 | 0.0219 | 36.689 | 24.631 | ||||

| 6.350 | 0.0250 | 41.759 | 20 | 28.035 | |||

| 7.798 | 0.0307 | 51.002 | 30 | 34.240 | |||

| 8.738 | 0.0344 | 56.946 | 38.231 | ||||

| 9.271 | 0.0365 | 63.301 | 40 STD | 40.0483 | |||

| 11.125 | 0.0438 | 71.852 | 48.238 | ||||

| 12.700 | 0.0500 | 81.530 | 60 XHY | 54.735 | |||

| 15.088 | 0.0594 | 95.969 | 80 | 64.429 | |||

| 12″ | 4.775 | 0.0188 | 12.750 | 324 | 37.570 | 25.222 | |

| 5.563 | 0.0219 | 43.657 | 29.309 | ||||

| 6.350 | 0.0250 | 49.713 | 33.375 | ||||

| 7.137 | 0.0281 | 55.739 | 37.420 | ||||

| 7.925 | 0.0312 | 61.735 | 41.445 | ||||

| 9.525 | 0.0375 | 73.824 | 49.562 | ||||

| 10.0312 | 0.0406 | 79.727 | 53.525 | ||||

| 12.700 | 0.0500 | 97.438 | 65.415 | ||||

| 14.275 | 0.0562 | 108.966 | 73.154 | ||||

| 14″ | 4.775 | 0.0188 | 14.000 | 356 | 41.308 | 27.732 | |

| 5.563 | 0.0219 | 48.012 | 32.233 | ||||

| 6.350 | 0.0250 | 54.685 | 20 | 36.713 | |||

| 7.137 | 0.0281 | 61.327 | 41.172 | ||||

| 7.925 | 0.0312 | 67.939 | 45.611 | ||||

| 9.525 | 0.0375 | 81.281 | STD | 54.568 | |||

| 11.125 | 0.0438 | 94.498 | 40 | 63.441 | |||

| 12.700 | 0.0500 | 107.381 | XHY | 72.090 | |||

| 15.875 | 0.0625 | 132.983 | 89.278 | ||||

| 16” | 4.775 | 0.0188 | 16.000 | 406 | 47.290 | 21.748 | |

| 5.563 | 0.0219 | 54.980 | 36.910 | ||||

| 6.350 | 0.0250 | 62.639 | 10 | 42.053 | |||

| 7.137 | 0.0281 | 70.0268 | 47.174 | ||||

| 7.925 | 0.0312 | 77.866 | 20 | 52.275 | |||

| 8.738 | 0.0344 | 85.677 | 57.519 | ||||

| 9.525 | 0.0375 | 93.213 |

30 STD |

62.578 | |||

| 11.125 | 0.0438 | 108.433 | 72.797 | ||||

| 12.700 | 0.0500 | 123.289 |

40 XHY |

82.770 | |||

| 18″ | 5.563 | 0.0219 | 18.000 | 457 | 61.948 | 41.588 | |

| 6.350 | 0.0250 | 70.0593 | 47.393 | ||||

| 7.137 | 0.0281 | 79.208 | 53.176 | ||||

| 7.925 | 0.0312 | 87.792 | 20 | 58.939 | |||

| 9.525 | 0.0375 | 105.144 | STD | 70.0588 | |||

| 11.125 | 0.0438 | 122.369 | 30 | 82.152 | |||

| 12.700 | 0.0500 | 139.198 | XHY | 93.450 | |||

| 14.275 | 0.0562 | 155.904 | 40 | 104.666 | |||

| 15.875 | 0.0625 | 172.754 | 115.978 | ||||

| 20″ | 6.350 | 0.0250 | 20.0000 | 508 | 78.547 | 52.733 | |

| 7.163 | 0.0282 | 88.458 | 59.386 | ||||

| 7.925 | 0.0312 | 97.719 | 65.604 | ||||

| 9.525 | 0.0375 | 117.075 | 20 STD | 78.598 | |||

| 11.125 | 0.0438 | 136.305 | 91.508 | ||||

| 12.700 | 0.0500 | 155.106 | 30 XHY | 104.130 | |||

| 15.088 | 0.0594 | 183.378 | 40 | 123.110 | |||

| 15.875 | 0.0625 | 192.640 | 129.328 | ||||

| 17.475 | 0.0688 | 211.368 | 141.901 | ||||

| 24″ | 6.350 | 0.0250 | 24.000 | 610 | 94.456 | 63.413 | |

| 7.137 | 0.0281 | 106.029 | 71.183 | ||||

| 7.925 | 0.0312 | 117.573 | 18.932 | ||||

| 9.525 | 0.0375 | 140.0938 | 20 STD | 64.618 | |||

| 11.125 | 0.0438 | 164.176 | 110.0219 | ||||

| 12.700 | 0.0500 | 186.923 | XHY | 125.490 | |||

| 15.875 | 0.0625 | 232.410 | 156.028 | ||||

| 17.475 | 0.0688 | 255.148 | 40 | 171.293 | |||

| 19.050 | 0.0750 | 277.401 | 186.233 | ||||

| 30″ | 6.350 | 0.0250 | 30.0000 | 762 | 118.318 | 79.433 | |

| 7.137 | 0.0281 | 132.851 | 89.189 | ||||

| 7.925 | 0.0312 | 147.353 | 10 | 98.925 | |||

| 9.525 | 0.0375 | 176.731 | STD | 118.648 | |||

| 11.125 | 0.0438 | 205.983 | 138.286 | ||||

| 12.700 | 0.0500 | 234.647 | 20 XHY | 157.530 | |||

| 15.875 | 0.0625 | 292.066 | 30 | 196.078 | |||

| 17.475 | 0.0688 | 320.0817 | 215.380 | ||||

| 19.050 | 0.0750 | 348.988 | 234.293 | ||||

| 36″ | 6.350 | 0.0250 | 36.000 | 914 | 142.180 | 95.453 | |

| 7.137 | 0.0281 | 159.672 | 107.196 | ||||

| 7.925 | 0.0312 | 177.133 | 10 | 118.918 | |||

| 9.525 | 0.0375 | 215.525 | STD | 142.678 | |||

| 11.125 | 0.0438 | 247.790 | 166.353 | ||||

| 12.700 | 0.0500 | 282.372 | 20 XHY | 198.570 | |||

| 15.875 | 0.0625 | 351.723 | 236.128 | ||||

| 17.475 | 0.0688 | 386.487 | 259.467 | ||||

| 19.050 | 0.0750 | 420.0576 | 282.353 | ||||

| 42″ | 7.925 | 0.0312 | 42.000 | 1067 | 206.914 | 138.911 | |

| 9.525 | 0.0375 | 248.319 | STD | 166.708 | |||

| 12.700 | 0.0500 | 33.097 | XHY | 221.610 | |||

| 19.050 | 0.0750 | 492.163 | 330.0413 | ||||

| 48″ | 9.525 | 0.0375 | 48.000 | 1219 | 284.112 | STD | 190.0738 |

| 11.125 | 0.0438 | 331.404 | 222.487 | ||||

| 12.700 | 0.0500 | 377.822 | XHY | 253.650 | |||

| 19.050 | 0.0750 | 563.750 | 378.473 | ||||

| 22.225 | 0.0875 | 655.969 | 440.0383 | ||||

| Kilogram/meter |

Copper Nickel 90/10 Pipe Outside Diameter milimeter |

Schedule |

Copper Nickel 90/10 Pipe Wall Thickness milimeter |

inch |

|---|---|---|---|---|

| 0.050 | 13.72 | 10S | 01.65 | 1/4 |

| 0.081 | 13.72 | 80S | 3.02 | 1/4 |

| 01.12 | 17.15 | 80S | 3.20 | 3/8 |

| 01.30 | 26.67 | 10S | 2.11 | 3/4 |

| 01.65 | 201.34 | 80S | 3.73 | 1/2 |

| 2.23 | 26.67 | 80S | 3.91 | 3/4 |

| 01.29 | 201.34 | 40S | 2.77 | 1/2 |

| 01.71 | 26.67 | 40S | 2.87 | 3/4 |

| 0.086 | 17.15 | 40S | 2.31 | 3/8 |

| 0.064 | 13.72 | 40S | 2.24 | 1/4 |

| 2.13 | 33.40 | 10S | 2.77 | 1 |

| 0.064 | 17.15 | 10S | 01.65 | 3/8 |

| 2.73 | 42.16 | 10S | 2.77 | 1¼ |

| 4.30 | 33.40 | 160 | 6.352) | 1 |

| 3.29 | 33.40 | 80S | 4.55 | 1 |

| 3.44 | 42.16 | 40S | 3.56 | 1¼ |

| 2.54 | 33.40 | 40S | 3.38 | 1 |

| 4.53 | 42.16 | 80S | 4.85 | 1¼ |

| 01.02 | 201.34 | 10S | 2.11 | 1/2 |

| 3.16 | 48.26 | 10S | 2.77 | 1½ |

| 5.49 | 48.26 | 80S | 5.08 | 1½ |

| 4.11 | 48.26 | 40S | 3.68 | 1½ |

| 5.69 | 42.16 | 160 | 6.352) | 1¼ |

| 3.99 | 60.033 | 10S | 2.77 | 2 |

| 5.52 | 60.033 | 40S | 3.91 | 2 |

| 7.60 | 60.033 | 80S | 5.54 | 2 |

| 101.29 | 60.033 | 160 | 8.742) | 2 |

| 5.35 | 73.03 | 10S | 3.05 | 2½ |

| 8.77 | 73.03 | 40S | 5.16 | 2½ |

| 101.59 | 73.03 | 80S | 7.01 | 2½ |

| 6.56 | 88.90 | 10S | 3.05 | 3 |

| 201.67 | 88.90 | 160 | 101.132) | 3 |

| 15.51 | 88.90 | 80S | 7.62 | 3 |

| 13.78 | 1001.60 | 40S | 5.74 | 3½ |

| 7.53 | 1001.60 | 10S | 3.05 | 3½ |

| 18.92 | 1001.60 | 80S | 8.08 | 3½ |

| 16.32 | 114.30 | 40S | 6.02 | 4 |

| 101.47 | 88.90 | 40S | 5.49 | 3 |

| 8.50 | 114.30 | 10S | 3.05 | 4 |

| 22.10 | 1401.30 | 40S | 6.55 | 5 |

| 34.05 | 114.30 | 160 | 13.492) | 4 |

| 49.87 | 1401.30 | 160 | 15.882) | 5 |

| 112.97 | 219.08 | 160 | 23.012) | 8 |

| 28.69 | 168.28 | 40S | 7.11 | 6 |

| 22.67 | 114.30 | 80S | 8.56 | 4 |

| 14.04 | 168.28 | 10S | 3.4 | 6 |

| 54.75 | 168.28 | 120 | 14.27 | 6 |

| 43.21 | 168.28 | 80S | 10.097 | 6 |

| 301.44 | 1401.30 | 80S | 9.53 | 5 |

| 68.59 | 168.28 | 160 | 18.262) | 6 |

| 901.30 | 219.08 | 120 | 18.23 | 8 |

| 65.63 | 219.08 | 80S | 12.7 | 8 |

| 43.20 | 219.08 | 40S | 8.18 | 8 |

|

Copper Pipes O.D. (in.) |

Copper Nickel 90/10 Pipe Wall Thickness of Pipe (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .035 | .109 | .028 | .065 | .049 | .095 | .083 | .120 | |

| 1/4 | 4800 | 3700 | 9500 | 7000 | ||||

| 1/8 | 10100 | 7900 | ||||||

| 3/8 | 3100 | 6100 | 4400 | |||||

| 5/16 | 3700 | 7300 | 5400 | |||||

| 3/4 | 3000 | 2200 | 4600 | 4000 | ||||

| 1/2 | 2300 | 4400 | 3200 | |||||

| 1 | 3900 | 2200 | 3400 | 2900 | 4300 | |||

| Copper Nickel 90/10 Pipe Surface Finish | Exterbal Surface(OD) | Internal Surface(ID) | |||

|---|---|---|---|---|---|

| Roughness Average(RA) | Roughness Average(RA) | ||||

| μm | μ inch | μm | μ inch | ||

| BA | Beight Annealed | 0.8 | 32 | 1.0, 0.6, 0.8, 0.5 | 32, 40, 20, 25 |

| EP | Electro Polish | 0.8 | 32 | 0.25, 0.38, 0.13, 0.20 | 10, 7, 15,5 |

| AP | Annealed & Pickled | 1.0 or Not defined | 40 or Not defined | Not defined | Not defined |

| MP | Mechanical Polish | 0.8 | 32 | 0.8, 1.0, 0.5, 0.6 | 32, 40, 20, 25 |

| Copper Nickel 90/10 Pipe Types | Copper Nickel 90/10 Pipe Out diameter | Wall thickness | Copper Nickel 90/10 Pipe Length |

|---|---|---|---|

| Copper Nickel 90/10 Seamless Pipe (as per need) | 5.0 milimeter ~ 203.2 milimeter | as per need | Upto 6 Meters |

| Copper Pipes NB Sizes (ready Stock) | 1/8” ~ 8” | SCH 10 / SCH 5 / SCH 80 //SCH 40 / SCH 160 | |

| Cupro Nickel 90/10 Welded Pipe (ready Stock + as per need | 5.0 milimeter ~ 1219.2 milimeter | 1.0 ~ 15.0 milimeter |