Nickel 211 is a nickel-manganese alloy that offers excellent resistance to corrosion and high-temperature environments. It is similar to Nickel 200, but with added manganese for enhanced performance in certain applications.

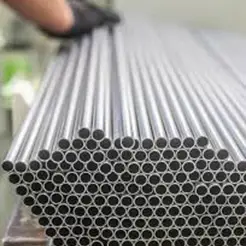

Nickel 211, like other nickel alloys, is commonly used in various industries,

including chemical processing, electronics, and marine applications.

Its excellent corrosion resistance, combined with good mechanical properties, make it suitable for handling corrosive chemicals, manufacturing electrical connectors, and producing components for marine environments.

Nickel 211 exhibits excellent resistance to a wide range of corrosive environments, including sulfur, acids, alkaline solutions, and saltwater. It maintains its corrosion resistance in both reducing and oxidizing conditions.

Mechanical Properties (Annealed)

|

Tensile Strength |

95,000 psi (655 MPa) maximum |

|

Yield Strength |

45,000 psi (310 MPa) maximum |

|

Elongation |

30% minimum (in 2-inch gauge length) |

|

Hardness |

HRB 80 maximum |

Physical Properties

|

Density |

0.315 lb/in³ |

|

Melting Range |

2600°F (1427°F) |

|

Thermal Conductivity |

342 BTU-in/ft2-h (at 68°F) |

|

Electrical Resistivity |

40 μΩ-in (at 68°F) |

|

Solution Temperature |

Approximately 1600°F (871°C) |

|

Modulus of Elasticity |

30 x 10^6 psi |

Chemical Composition (% by weight)

|

|

||

|

Element |

Min |

Max |

|

Mn |

4.25 |

5.25 |

|

Ni |

93.7 |

- |